Control Valves

Sart Von Rohr Control Valves

What is the control valve ?

How Is Working 2 Way Pneumatic Globe Control Valve

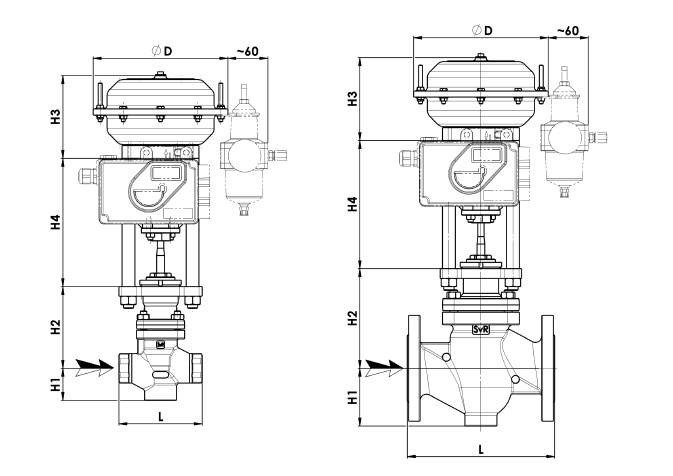

The medium flows through the valve in the direction indicated by the arrow on the body. The valve plug position determines the cross-sectional area between the seat and plug.

The purpose of a “Control” valve is to control. It might control flow, level, pressure or temperature depending on the purpose of loop it is installed in. The valve itself is normally a “globe” type valve body but with an air or electro-pneumatic operator. This operator is controlled through a loop that includes a primary sensor and the control logic. Control valves are the most common type of final control element.

Control valves may be the most important, but sometimes the most neglected, part of a control loop. The reason is usually the instrument engineer’s unfamiliarity with the many facets, terminologies, and areas of engineering disciplines such as fluid mechanics, metallurgy, noise control, and piping and vessel design that can be involved depending on the severity of service conditions. Any control loop usually consists of a sensor of the process condition, a transmitter, and a controller that compares the “process variable” received the transmitter with the “set point,” i.e., the desired process condition. The controller, in turn, sends a corrective signal to the “final control element,” the last part of the

loop and the “muscle” of the process control system. While the “sensors” of the process variables are the eyes, the “controller” the brain, then the “final control element” is the hands of the control loop. This makes it the most important, alas

sometimes the least understood, part of an automatic control system. This comes about, in part, due to our strong attachment to electronic systems and computers causing some neglect in the proper understanding and proper use of the all important hardware.

Pneumatic Actuator Fail Safe ; Depending on how the springs are arranged in the pneumatic actuator, the valve has two different fail-safe positions effective upon air supply failure.

Positioner : Valve Positioners are devices used to put the valve in the correct position by increasing or decreasing the air load pressure on the actuator. Valve positioners are used for controlling valve where accurate and rapid control is required without error or hysteresis.

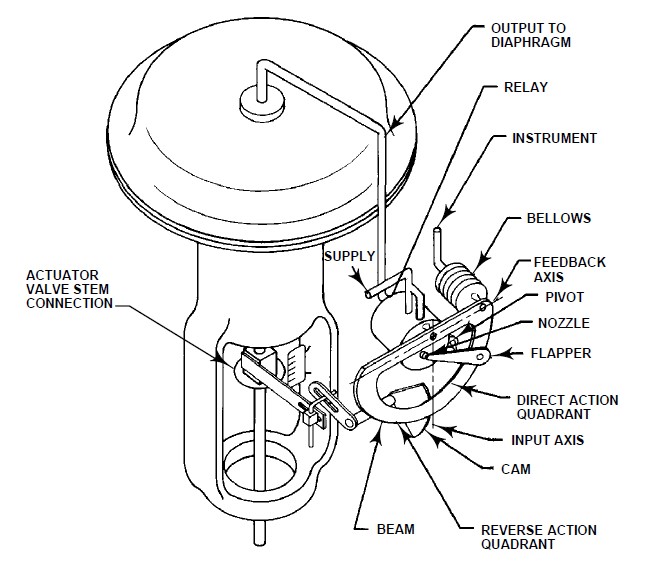

Usually, an I/P converter sends the opening-closing request to the valve but cannot confirm the position of the valve actuator. The process controller tells the required position to the positioner, and the positioner senses the current position of the actuator and compares with the required setpoint. Then give the control action through the flapper-nozzle amplification system. A positioner can reduce the effect of many dynamic variations. This include change in packing friction due to dirt, corrosion, lubrication, or lack of lubrication.

The above shown is a pneumatic valve positioner. The current position of the actuator is transferred through beam and cam. The control signal is given through a bellow. The supply pressure to the valve is controlled by the flapper-nozzle system. The flapper nozzle controls the supply pressure by referring the feedback the actuator and setpoint signal.

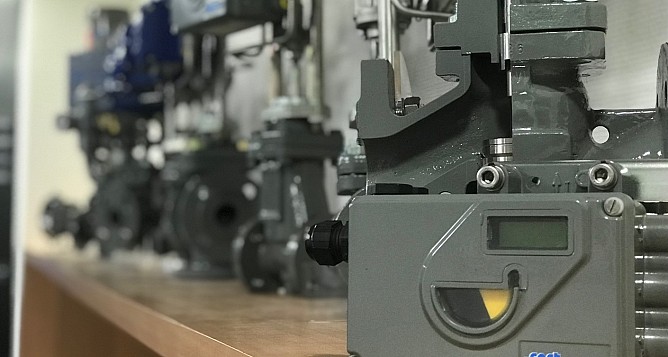

Bafcon has many type of control valves, I/P and P/P positioners in own warehouse.

Fast supply for ; two way globe control valve , three way globe control valves ( diverting and mixing type ) Eckardt Foxboro Sart SRI 986 , SRI 990, SRD 960, SRD991, SRD998 , SRP 981 pneumatic ,mechanic and smart positioners.

There are other types of valve positioners:

Electro-pneumatic positioner : Perform the same function as the pneumatic type, but uses an electrical current of 4-20mA instead of air as the input signal which uses i/p converter.

Electronic positioner : This positioner replaces the i/p converter with a microprocessor inside the positioner itself to perform the same function as the above positioner.

Digital positioner : This type of positioner to position the valve actuator and monitor and record data. They are very accurate, use less air than analogue positioner. Digital positioner are smart. They has auto calibration, LCD screen , Hart , Profibus , Modbus comminications.

Some Abbreviation in Valve Industry ;

– Manufacturers standardization society of the Valve & Fitting (MSS)

– Society of Automotive Engineers(SAE)

– American Water Works Association(AWWA)

– American Iron and Steel Institute(AISI)

– American Petroleum Institute(API)

– British Standard(BS)

– Korean Industrial Standard(KS)

– Russia Standard(GOST)

– Deutsches Institute for Norman(DIN)

– Committee European De Normalization(CEN)

– Japan Industrial Standard(JIS)

– International Organization for Standardization(ISO)

– National Corrosion Engineering(NACE)

– American National Standards Institute (ANSI)

– American Society of Mechanical Engineers(ASME)