BUTTERFLY CONTROL VALVES

VERSATILE DESIGN FOR A WIDE RANGE OF APPLICATIONS

Our high capacity Butterfly Control Valves offer a lighter alternative to Globe Valves whilst still protecting against problems such as noise and cavitation when working with high pressure drops. Our Butterfly Control Valves are designed for a diverse range of industries and applications. There are options for temperatures as high as 800 °C and pressure drops of up to 150 bar, all designed to protect against the effects of cavitation and noise.

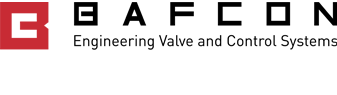

ROTROL VALVE

A major disadvantage of conventional butterfly and ball valves when used in throttling applications is the effect of cavitation which can commence at quite low values of differential pressure. This, coupled with high noise emissions may result in rapid mechanical wear and early failure of the valve components.

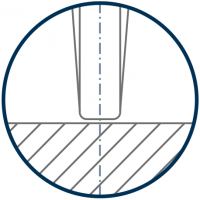

To offset these effects, we have developed a rotary control valve with improved performance capability. The innovative design incorporates a profiled vane which has cowls on its leading and trailing edges. These cowls are drilled with a large number of holes as can be seen above. The function of these cowls, which normally cover about one third of the 90º travel, is to split up the flow stream and dissipate the energy created by the pressure drop across the valve. This allows the valve to handle higher pressure drop and higher velocities without the onset of cavitation and noise. This specialised valve performs exceptionally well in severe service applications with its variable resistance trim, where the pressure drop tends to be high in the controlling position but where high capacity through puts at low pressure drops are also required.

SERIES 64 BUTTERFLY VALVE

TECHNICAL SPECIFICATION

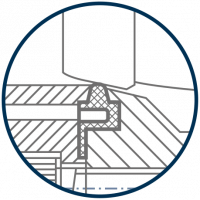

Valve type: Introseal metal-seat

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: IV

Temperature (ºC): -196 to 600

The Series 64 butterfly valve can operate at higher temperatures than Series 63 and is used for applications where a small leakage (Class IV) is allowed in the closed position or where a soft seat is impractical due to high temperatures or arduous service conditions. It can operate at temperatures of between -196°C and 600°C, and pressure drops of up to 100 bar.

SERIES 65 BUTTERFLY VALVE

TECHNICAL SPECIFICATION

Valve type: Introseal Firesafe

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: VI

Temperature (ºC): -196 to 235

The Series 65 valve is similar to Series 63 but with a back-up seat. This can maintain the integrity of the valve in the event of a fire destroying the soft seat. The back-up seat will allow only minimal leakage in the closed position and will also ensure that the valve remains operable after a fire until it can be removed and replaced safely.

SERIES 66 BUTTERFLY VALVE

TECHNICAL SPECIFICATION

Valve type: Introseal (no seat)

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: II

Temperature (ºC): -196 to 800

The Series 66 valve is designed for applications where leakage in the closed position is not a problem but controlling the amount of liquid of gas through the pipeline is essential. Up to 200°C, Class II leakage can be maintained in the closed position. It can operate at temperatures of between -196°C and 800°C (albeit with higher leakage above 200°C), and pressure drops of up to 150 bar.

OTHER FEATURES

OTHER FEATURES OF OUR BUTTERFLY CONTROL VALVE RANGE INCLUDE:

- High flow coefficient

- Anti-cavitation, low-noise vane design.

- Lighter weight and more compact than a globe valve.

- Superior seat and stem seal integrity.

- Profiled vane with cowls on leading and trailing edges to dissipate energy created by pressure drop across the valve.

- Baffle plates fitted for noise attenuation.

- High rangeability – excellent control between 5° and 90° of opening.

- Operating torque requirements are around half the conventional butterfly valve requirements, requiring smaller more compact actuators.

- Complete range of body materials.

►KATALOG